Shenzhen Lizhifeng Electronic Equipment Co., Ltd

Address: Floor 4, Building 2, Hengchangrong Industrial Zone, No. 128, Shajing Shangnan East Road, Bao'an District, Shenzhen

Tel.: 13925215926

Marketing hot sale: 13925286095

Email: marktong@smtlf.cn

Requirement solution method

Solving the shadow problem: moore clause of shadow

Real time bending compensation (2D 3D scheme): PadReferencing Z-Tracing

Easy to operate: RenewalGUI, color 3D pictures

Foreign matter detection: 30 Foreign matter detection function (option)

Test performance

Test items: volume, area height, offset, bridge, shape, coplanarity

Type of defects: missing printing, excessive tin, insufficient tin, continuous tin, poor shape, offset, coplanarity

Camera resolution: 15um 20um 25um

FOV size: 30 * 30mm (1.18 * 1.18inch) 40 * 40mm (1.57 * 1.57inch) 50 * 50mm (. 97 * 1.97inch)

Full 3D detection speed: 22.5-56.1cm/sec (detection speed varies with PCB and detection conditions)

Spacing of Xiaoyun paste: 100um (3.94mis), 150um (5.91mils), 200um (7.87mils)

Camera: 4 megapixel camera

Lighting: IR-RGBLEDDomeSstyedlunabion (option)

Z-axis resolution: 0.37 μ m

Height accuracy {correction module): 1 μ m

01005 Detection capacity:<10% at6o

Inspection size: 10x10mm 0.39 * 0.39inch

Detection height: 400um 15.75mils

Small pad spacing: 100um (150 μ M solder paste height) 3.94mils (5.91mils solder paste height)

Corresponding color base plate: Yes

Substrate correspondence

Track width adjustment: automatic

Rail fixation mode: front rail fixation/rear rail fixation (fixed during shipment)

Software

Supported input format: Gerberdata (274X, 274D, ODB option)

Programming software: ePM-SPI

Statistical management tools:

SPC@KART (Option)

-Histogram.X-bar&R-Char,Xbar&S-Chat.Cp&Cpk.%GageR&R

-Real time SPC&MultipleDisplay

SPC alarm

KART remote monitoring system (option)

Operation convenience:

LibraryManager@KART

KYCal: Auto calibrate camera/lighting/height

Operating system Windows7Ulimate64bit

Add-onSolutions

1D&2DHandyBarcodeReader : RemoteMonitoringSystem : Link@KART

1D&2DInlineBaroodeReader : WarpCompensation : SPC@KART

OflineProgrammingStation : ForeignMaterialInspection

OflineSPCPlusStation : ReviewStation

StandardCalibrationTarget : KARTProcessOptimizer

UPS : IR-RGBLight

When the automatic tin replenishing function is selected, it depends on the equipment specification. The size of PCBR varies with the detection performance.

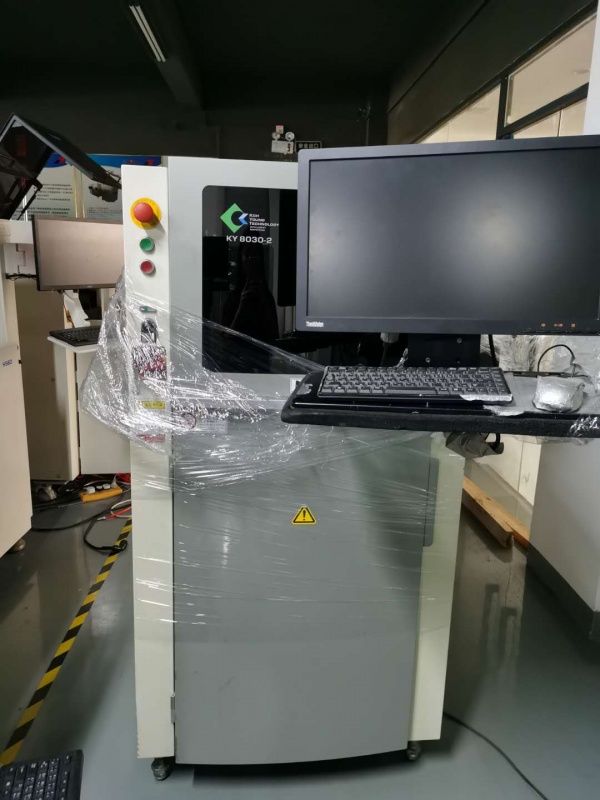

KY-8030-2 measurement software: KY8080 KY8030-2XL

MC-110-2.5D video observation, image saving, thickness measurement, data recording, background light, laser brightness control, area (square, irregular polygon, circle)/volume/spacing (X, Y axis)/angle measurement, 24 production lines/any number of products can be memorized.

SPC software HSPC2000: query, modify, delete, export (text and EXCEL table), preview and print data according to the specified product, production line and date range, and can count the average value, value, small value, variance, standard deviation, defective number, defective rate, skewness, kurtosis, Ca, Cp, Cpk, Pp and Ppk, and can draw, preview and print X-BAR control chart and R pipe drawing (the control parameters can be set by yourself).

Measuring principle:

The non-contact laser measuring instrument generates a linear beam from the laser and projects a certain angle to the target to be measured. Because there is a height difference between the target to be measured and the substrate, the observed target and the laser beam on the substrate appear intermittent drop correspondingly. According to the trigonometric function relationship, the observed drop can be used to calculate the height difference between the target to be measured and the surrounding substrate, so as to achieve non-contact rapid measurement.

Parameters:

Measuring principle: non-contact, laser beam

Measurement accuracy:± 0.002mm repeated measurement accuracy:± 0.004mm

Base size: 324mm× 320mm

Mobile platform: large range fast positioning, fine adjustment, electromagnetic locking

3D scanning stroke: 10mm 3D scanning drive: step servo drive, screw guide system

3D measurement: scanning, 3D contour reconstruction, arbitrary measurement

Image system: HD CCD, 640× 480 Pixel

Travel of mobile platform: 230mm× 200mm

Mobile platform size: 320mm× 320mm

Measurement method: 3D measurement or 2D measurement

Optical magnification: 25~110 times (adjustable in 5 gears)

Image size: 600× 480 Pixel power supply: 220V~50Hz

Lighting system: ring LED light source (PC control brightness)

Measuring light source: as low as 5.0 μ M High precision laser beam

System size: L372mm× W 557mm× H 462mm

Measurement software: MC-110-2.5D/SPC2000 (Windows2000/XP platform)

Power supply: 220/240/1 Phase 50/60HZ

Power: 2.2kw

Weight: 500kg

Volume: 705× 1200× 1540mm

Product name: 3D SPI

KY-8030L

Weight: 550KG

Power specification: 220Vac, 1phase, 50/60Hz

Shenzhen Lizhifeng Electronic Equipment Co., Ltd

Address: Floor 4, Building 2, Hengchangrong Industrial Zone, No. 128, Shajing Shangnan East Road, Bao'an District, Shenzhen

Tel.: 13925215926

Marketing hot sale: 13925286095

Email: marktong@smtlf.cn

Scan WeChat